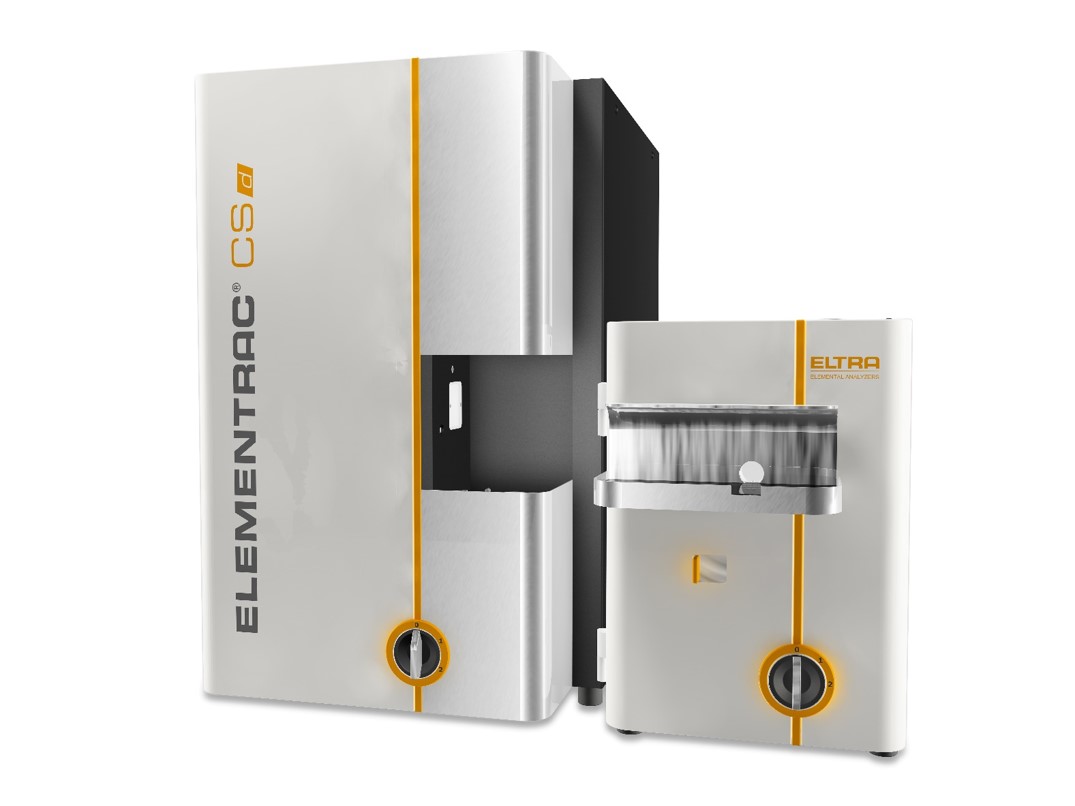

CS-d Carbon Sulphur Analyser

ELTRA’s ELEMENTRAC CS-d is the only analyser in the market for determination of carbon and sulphur in organic as well as inorganic samples. For this purpose, the ELEMENTRAC CS-d is equipped with both an induction and a resistance furnace (ELTRA Dual Furnace Technology), covering the full range of carbon and sulphur analysis.

Up to four highly sensitive infrared (IR) cells allow for precise measurement of both high and low carbon and sulphur concentrations in only one analysis. The measuring range of each cell may be adapted to the user’s specific requirements to ensure optimum measurement conditions for each application.

The ELEMENTRAC CS-d is supplied with the comprehensive and user-friendly ELEMENTS software which features statistics, groupings, reports, diagnosis tools and many additional functions.

APPLICATION EXAMPLES

Alloys, ashes, carbides, cast iron, cement, ceramics, coal, coke, copper, glass, gypsum, iron, limestone, metals, minerals, oil, ores, plant materials, refractory metals, rubber, sand, soils, steel, titanium, tobacco, …

PRODUCT ADVANTAGES

- General:

- full flexibility due to combined induction and resistance furnace: ELTRA Dual Furnace (EDF) Technology

- rapid, precise, accurate and reliable carbon & sulphur analysis in inorganic and organic samples

- up to four independent infrared cells with flexible measuring ranges

- gold IR path allows for increased cell live time for analysis of halogen or acid containing samples

- simultaneous carbon and sulphur determination with minimal sample preparation

- low maintenance

- robust design allows usage in production control and laboratory

- Induction Furnace:

- adjustable and rampable induction furnace (0-100%) for optimized combustion of every kind of inorganic samples (maximum temperature above 2,000 °C)

- precise carbon and sulphur analysis in inorganic samples due to intelligent oxygen supply during inductive combustion

- optional automatic vacuum cleaning system ensures higher measurement precision

- heated and easily accessible dust trap allows for improved sulphur detection

- optimized catalyst reactor permits more accurate carbon detection

- Resistance Furnace:

- temperature of resistance furnace adjustable from 600 °C up to 1,550 °C in steps of 1 °C

- low blank sample port assures reliable low carbon measurement in the resistance furnace

- XXL balcony for storage of samples

- ELEMENTS software:

- comprehensive analysis and diagnosis tools (supporting data and application export, comment fields, and many more)

- Report Designer

- LIMS

- single and multipoint calibration

FEATURES

| Measured elements | carbon, sulphur |

| Samples | inorganic, organic |

| Furnace alignment | horizontal (resistance furnace) and vertical (induction furnace) |

| Sample carrier | ceramic boats / crucibles |

| Field of application | agriculture, chemistry / plastics, coal / power plant, construction materials, engineering / electronics, environment / recycling, geology / mining, glass / ceramics, medicine / pharmaceuticals, steel / metallurgy |

| Furnaces | induction furnace, above 2,000 °C resistance furnace (ceramic tube), adjustable up to 1,550 °C (steps of 1 °C) |

| Detection method | solid state infrared absorption |

| Number of IR cells | 1 – 4 |

| Material of IR path | gold |

| Typical analysis time | induction furnace 40 – 50 s resistance furnace 60 – 120 s |

| Chemicals required | magnesium perchlorate, platinized silica (alternatively copper oxide), sodium hydroxide |

| Gas required | compressed air (4 – 6 bar / 60 – 90 psi) oxygen 99.5 % pure (2 – 4 bar / 30 – 60 psi) |

| Power requirements induction furnace | 230 V, 50/60 Hz, 16 A fuse |

| Power requirements resistance furnace | 230 V, 50/60 Hz, 20 A fuse |

| Dimensions (W x H x D) | 89 x 84 x 79 cm |

| Weight | ~ 200 kg |

| Required equipment | balance (resolution 0.0001g), monitor, PC |

| Optional accessories | Autoloader for 36 crucibles, carrier gas purification, HTF-540 pre-heating furnace |

FUNCTION PRINCIPLE

Operation Carbon / Sulphur Analyzer ELEMENTRAC CS-d

The ELEMENTRAC CS-d utilizes two different furnaces (resistance and induction) which share one detection unit consisting of up to four independent IR cells. Inorganic samples like steel, cast iron, cement are usually processed in the induction furnace of the CS-d. After applying the sample to a ceramic crucible, it is logged in the ELEMENTS software with name and weight. This is followed by adding accelerators like iron and tungsten. The ceramic crucible with sample and accelerator is placed on the pedestal and the measurement is started in the software. All further steps are controlled by the ELEMENTS software; the measured carbon and/or sulphur result is displayed after approx. 50 seconds. One or multiple results can be exported to LIMS or to a report.

Organic samples are usually processed in the resistance furnaces of the CS-d at a defined temperature up to 1,550 C. The samples (such as coal) are weighed in ceramic boats without accelerator. The weight is transferred from the interfaced balance to the PC or can be entered manually. The sample is then placed directly on the balcony in front of the furnace and the measurement can be started. A green LED light indicates when the analyser is ready for measurement and the ceramic boat with the sample can be introduced into the hot furnace with the help of a stick. The typical analysis time is 60 to 180 seconds, depending on the sample material.

Measuring principle Carbon / Sulphur Analyzer ELEMENTRAC CS-d

Regardless of which furnace is used in the ELEMENTRAC CS-d, the carbon and sulphur in the sample forms gaseous molecules like SO2 and CO2 during combustion. The released amounts of CO2 and SO2 are measured in up to 4 element-selective infrared cells. Usually, two IR cells are used for measuring one gas (CO2 or SO2) to ensure that both very low and very high concentrations are analysed precise and correctly.

When the induction furnace of the CS-d is used, the carrier gas (oxygen) and the combustion products (CO2, traces of CO, and SO2) are first led through a metallic filter to remove all solid particles. Afterwards, a tube filled with magnesium perchlorate removes traces of water. The dried combustion gas then passes up to two infrared cells for sulphur (SO2) measurement. Afterwards, a heated catalyst (usually platinized silica) oxidizes the traces of carbon monoxide (CO) to CO2 and the SO2 molecules to SO3. The SO3 gas is absorbed by cellulose and the CO2 is measured in up to two element selective IR cells. Finally, the combustion gas is led to the exhaust and the ELEMENTS software calculates the resulting carbon and sulphur concentrations.

Whereas the induction furnace of the ELEMENTRAC CS-d is suitable for analysing inorganic samples like steel, cast iron and ceramics, the resistance furnace is used for combustion of organic samples like coal, coke or soil. When a coal sample is combusted at temperatures of approx. 1350° C, CO2 and SO2 are released but usually no carbon monoxide (CO) is formed. The combustion gases of the resistance furnace first pass a ceramic filter for absorption of particles, followed by a glass tube with magnesium perchlorate.

After that the dried combustion gases pass the same path as those from the induction furnace. Usually, the catalyst furnace is switched off during usage of the resistance furnace because oxidation of CO is not required.

However, the risk of incomplete combustion and formation of carbon monoxide increases at lower temperatures (~600 °C); in such cases the catalyst furnace may be switched on.